Automotive Business Area

-

HANYANG S&C – HAMAN Plant

Producing the best quality materials in the world In this plant, we produce disc and drum castings for automotive brake system and own environment-friendly technology, advanced technology and the latest automated facilities. We realize the world’s best material quality and the optimized production, being the leader in the field contributing to development of the basic industry.Business Area Production capacity Production line HANYANG S&C- HAMAN Plant 40,000 tons / year Brake Disc, Drum casting materials / Inner mold (Cr-Mo FC material)

Main process

Casting Line

- Automated injection system (Heating method based on inductor)

- Securing 60 minutes of cooling time by establishing cooling line of 89 m

- Application of variable invertor method for cooling drum

-

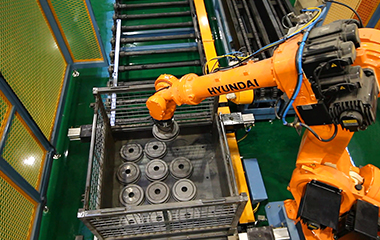

Establishment of automated deburring and automatic robot loading system

- Capacity : 40,000 Ton / year

- Cycle Time : 10sec / mold

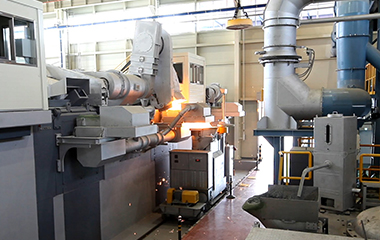

Core Line

- Realization of environment improvement, quality stabilization and cost reduction by applying the nation’s first entire line heater (electricity) type

-

Realization of figures with consistent quality based on full automated process

- Capacity : 2,100,000 ea / year

- Cycle Time : 32sec / 3ea

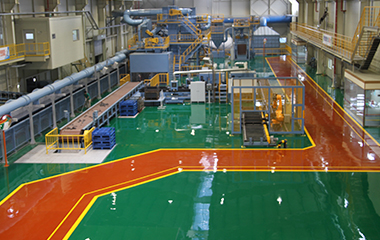

Plant environment

- Equipped with environment-friendly dust-collecting equipment such as molding, melting, sand treatment and post-treatment (8,700㎥/min)

- Equipped with automated discharge system of air circulation type

- 95% Automation rate (unified line structure from injection to product packing)li>

Main process

-

Inner mold line

-

Molten metal transfer process

-

Cooling drum

-

Cooling drum

-

Automated unloading process

-

Panoramic view of production site